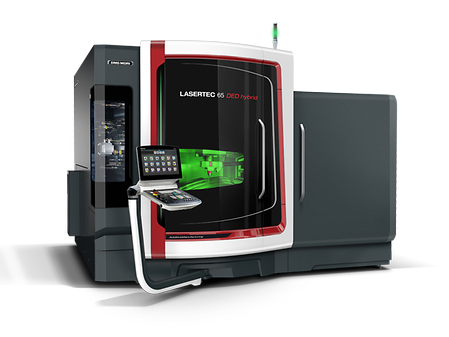

Apr 14, 2014 With the LASERTEC 65 AdditiveManufacturing, DMG MORI presents a hybrid machine, which currently is unique and incorporates generative laser. Additive manufacturing opens up new possibilities for high complexity and individuality in the production of e.g. Integral parts as well as similar light-weight components made from metallic high performance materials. The additive market is growing quickly. SAUER LASERTEC, a member of the DMG MORI SEIKI AG, integrates for the first time the additive manufacturing into a high-tech 5-axis. DMG MORI has already shown an active interest in the impact of additive on the industry with the introduction of its LASERTEC 65 3D system, a hybrid AM and 5-axis milling machine, which combines the flexibility of AM with the precision of metal cutting.

Flexibility by utilizing combination of additive and milling machining process for 3D-parts in finished quality

- The laser head is handled by a fully automatic shuttle - without manual intervention

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent from direction of laser deposition welding

- Full 5-axis milling machine in rigid monoBLOCK-design with < 129.2 ft² footprint

- Process monitoring and adaptive process-control (Closed Loop)

- User friendly and specifically developed software with operator-orientated user interface and CELOS integration

Process monitoring for highest process safety and quality management

Dmg Lasertec 65

- Continuous measuring and monitoring of the laser buildup process as well as automatic regulation of the laser power in real-time for homogeneous part qualities

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

Dmg Lasertec 65 3d Price List

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completeted integrated PLM software integration

Comments are closed.